GIVES YOU THE EDGE YOU NEED

PRODUCED BY HARDWIRE®

Unflinching strength, ultra lightweight design, revolutionary technology—Hardwire® Hard Armor brings together everything you need to perform your best when it counts the most.

HARDWIRE® Hard Body Armor

-

HARDWIRE® LIGHTWEIGHT MULTI CURVE PLATE

Vendor:HardwireRegular price $0.00Regular priceUnit price / per -

HARDWIRE® STANDARD MULTI CURVE PLATE

Vendor:HardwireRegular price $0.00Regular priceUnit price / per -

HARDWIRE® FLAT PLATE

Vendor:HardwireRegular price $0.00Regular priceUnit price / per -

HARDWIRE® 3A+ MULTI CURVE PLATE

Vendor:HardwireRegular price $0.00Regular priceUnit price / per -

HARDWIRE® PAK

Vendor:HardwireRegular price $0.00Regular priceUnit price / per -

HARDWIRE® LEVEL 3+ MULTI CURVE PLATE

Vendor:HardwireRegular price $0.00Regular priceUnit price / per -

HARDWIRE® RIFLE RESISTANT STEEL BODY ARMOR PLATE

Vendor:HardwireRegular price $0.00Regular priceUnit price / per -

HARDWIRE® RIFLE RESISTANT STEEL SIDE ARMOR PLATE

Vendor:HardwireRegular price $0.00Regular priceUnit price / per

EVOLUTION BECOMES REVOLUTION

In a perfect world body armor stops every bullet and weighs nothing. In the real world body armor is heavy, bulky, hot and uncomfortable for the officer who needs to wear it every day.

In 2016, Hardwire® introduced revolutionary soft body armor. Using proprietary manufacturing technology, Hardwire set a new standard for shock dissipation in ballistic panels that resulted in unprecedented stopping power, combined with the most lightweight and low-profile armor on the market. With the 2021 release of the new soft body armor package, Hardwire launches the lightest, thinnest, and coolest body armor package available to the law enforcement community.

MICRO MECHANICAL STRUCTURE

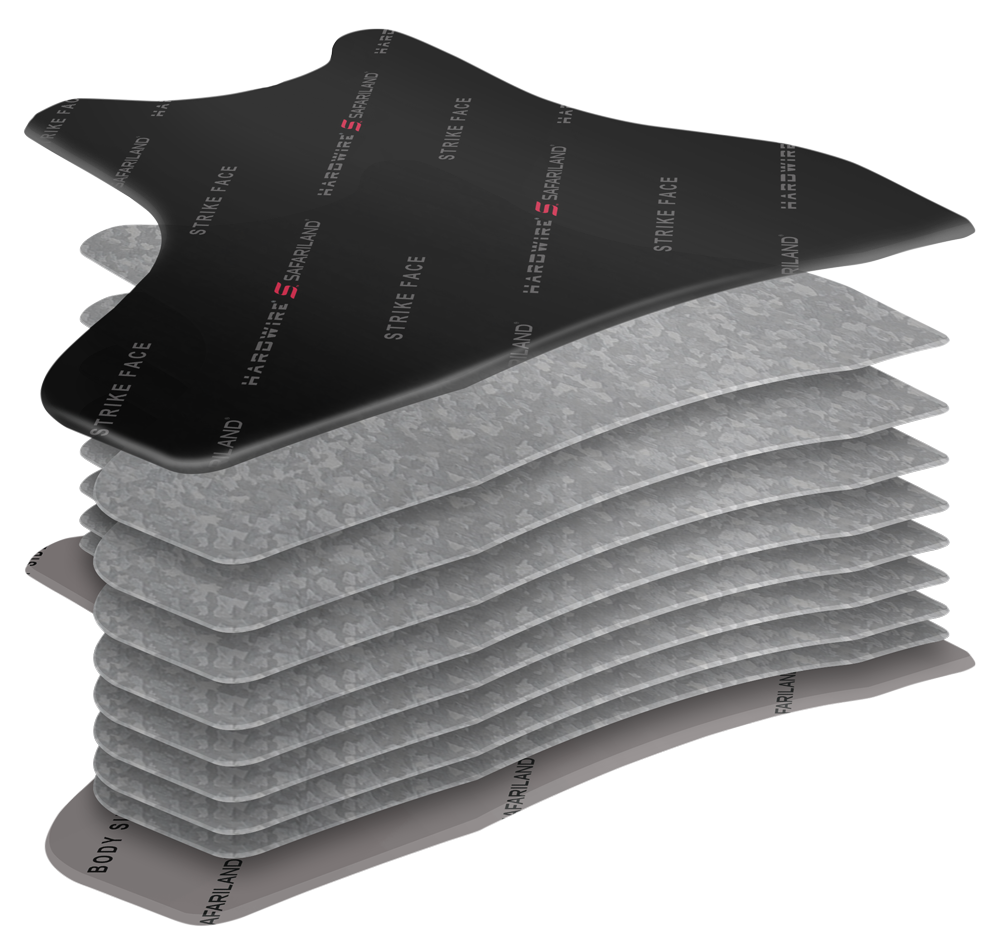

Individual layers of Dyneema® fibers are pressed under 25 million pounds of force at precise temperatures, turning the multiple layers of material into a single, stronger system.

-

SHOCK DISSIPATION

Impact energy is spread laterally across the panel, improving ballistic protection and reducing trauma.

-

LIGHTWEIGHT

Ballistic panels are up to 30% lighter than any soft armor on the market with an area density starting at 0.51 lbs/ft2.

-

POSITIVE BUYANCY

With a density that is lower than water, Hardwire ballistic panels are buoyant enough to float.

TRUSTED BY THE BEST

The Hardwire® body armor package was originally developed for use by the elite U.S. Special Operations Command (SOCOM) and United States Marine Corps (USMC). Driven by military requirements, the armor has the ability to stop bomb and grenade fragments in addition to bullets. This military-grade system and its derivatives are the trusted protective solutions used in the field by both military services today. Leveraging its high-volume manufacturing capabilities and military pedigree, Hardwire now offers the soft body armor package to meet the needs of law enforcement and security professionals.

SHOCK DISSIPATION PHYSICS

The Hardwire® manufacturing process and topological ordering of the materials causes bullets to be flattened on the surface of the panel. How does this work? When a round—rotating at 50,000 rpm—contacts the armor, it is arrested in the first ¼ turn, resulting in massive torsional stress on the bullet jacket. The stress waves are also transferred to the armor and along the fibers. Traveling at hypersonic speeds, the stress waves spread load and then are reflected back at the projectile itself. This reflected shock wave is transferred into the bullet resulting in stress—that combined with the torsional loads from arrested rotation—opens the jacket and flattens the projectile.

In other manufacturers’ body armor, the product has a tendency to bunch up, as the armor fibers are twisted by a bullet’s rotational force. Hardwire ballistic panels prevent this distortion by utilizing a leather-like construction. Should another round hit your armor, the plate is ready to protect you, as if you had just put it on. No other soft body armor on the market has this critical attribute.

INNOVATIVE MANUFACTURING PROCESS

While other manufacturers take individual layers of material and sew or place them together, Hardwire uses extremely high pressure to build a micro mechanical structure within the armor. Individual layers of Dyneema® fibers, under 25 million pounds of pressure, are turned from multiple layers of material into a single system. This innovative and proprietary manufacturing process is the key to the armor’s ability to stop and flatten bullets and shrapnel, as the fibers are stronger when they all act as one instead of independently.

UNPRECEDENTED STOPPING POWER

At Hardwire®, every shot matters. In testing they measure the back face deformation of every shot on every armor panel, and this next generation armor has the lowest back face signature of any ballistic panel package. Unlike other soft armor packages, projectiles are stopped in the first ply. This means that the bullet’s energy and the shock wave spreads out laterally across the maximum amount of material before reaching the body. Bullets are caught and flattened. Why is this important? This minimizes injury and preserves your ability to stay in the fight.

RIGOROUSLY TESTED

Hardwire® body armor system is being called the “Honey Badger” package, named after the animal renowned for its thick skin and ferocious defensive abilities. Hardwire body armor is rigorously and frequently tested. The product undergoes lot acceptance tests (LAT) weekly by independent laboratories, as required by the U.S. Special Forces and the USMC, far exceeding the annual testing mandated by NIJ law enforcement standards. The armor has successfully passed multiple military first article tests (FATs), the full Level IIIA NIJ 0101.06 certification test, and was recently selected by the U.S. Army for the downselect phase of the Modular Scalable Vest (MSV) program. The Gen 4 body armor is the most extensively tested armor package available to the law enforcement community.

LIGHTEST WEIGHT BODY ARMOR ON THE MARKET

After the rigid body armor plate has been created, it undergoes a softening process, similar to leather when a hide is dried. Once the armor goes through the softening process, it stays soft. By applying the most advanced techniques of making military-grade hard armor to manufacturing soft armor, Hardwire® has manufactured the thinnest, lightest, coolest and most comfortable Level IIIA body armor on the market. The Hardwire Level IIIA and Hardwire Level II weigh in at .68 lbs/ft2 and .51 lbs/ft2 respectively. These systems remain the lightest on the market and are up to 30% lighter than legacy systems.

"Less weight is a good thing. It definitely changes when we wear out vests, how long we wear them, and how comfortable it is."

Tom Northam, Deputy Chief of Protective Services at NASA Goddard Space Flight Center